Mechanical interlocking contactor

The mechanical interlocking contactor is mainly used for AC 50Hz or 60Hz, and the rated operating voltage to 660V, rated operating current to the following 95A circuit, for motor reversible control. Its mechanical interlocking mechanism ensures the reliability of the conversion of the two reversible contactor.

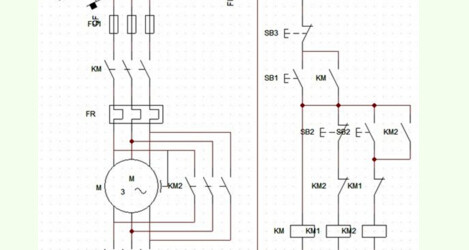

Two contactor combination in the control of the motor is reversed called reversible contactor. The mechanism that is installed between two contacts, called mechanical linkage. If there is no the device, press the control button on the left of the contactor and press the control button on the right side of the contactor, the two contactors will pull in, the main circuit is short circuited. This device is to prevent and pull two contactors.

CJX2-N (LC2-D) series reversible chain AC contactor is suitable for AC 50Hz or 60Hz, voltage to 690V, current to 95A circuit, and can be used for motor reversible control. Its mechanical interlocking structure, which ensures the reliable operation of the two reversible contactor.

Products comply with GB14048.4 standards.

Some of the more commonly used models are:

CJX2-09, CJX2-12, CJX2-18, CJX2-25, CJX2-32

CJX2-40, CJX2-50, CJX2-65, CJX2-80, CJX2-95

LC2-D09, D12 LC2-, D18 LC2-, D25 LC2-, D32 LC2-

D40 LC2-, D50 LC2-, D65 LC2-, D80 LC2-, D95 LC2-

Model rated operating current AV-3A, 400V control power KW auxiliary contact number notes

400V 415V 440V 690V 230V

CJX2-09N 5.5 NC 92.2444 installation method except the screws, the installation of the 35mm

CJX2-12N 5.5 7.5 5.5 NC

CJX2-18N 7.599 1847.5 NC

CJX2-25N 255.511111115 NC

CJX2-32N 18.5 327.5151515 NC

CJX2-40N 18.52230 NO+NC addition screw is equipped with 75mm mounting rail

CJX2-50N 501522223033 NO+NC

CJX2-63N 6318.530303737 NO+NC

CJX2-80N 802237374545 NO+NC

CJX2-95N 952545454545 NO+NC

Three: CJX2-N (LC2-D) reversible AC contactor appearance and installation size

QJX2 series star delta motor starter

Large power motor starting current is very big, in order to avoid the impact of large current on the line, the motor angle method is changed to start with a certain inertia, the rotation speed of a certain inertia, then turn to the angle of the start, the starting current of the 1/3. From 3 contacts, 1 time relay and button.

QJX2 series star delta starter (hereinafter referred to as starter), is suitable for AC 50Hz or 60Hz, rated insulation voltage of 660V (690V), the AC-3 type of three-phase squirrel cage induction motor with rated working voltage of 380V, power 80KW, and the following is used to control the stator winding from “Star” to “triangle” for starting and stopping. After assembling the thermal relay of the corresponding specification, the overload protection of the motor and the related circuit can be protected.

The starter and QJX4, LC3-D have the same functional specifications can be equated with the use of.

The function and principle of Starter Motor are respectively:

1, role:

The motor starter is device for auxiliary motor starting, the motor start smoothly, little impact on the grid, but also to achieve the soft parking of motor, brake, overload and lack of protection. The motor starter is mainly used for large motor and asynchronous motor.

2, working principle:

The distance between the plate to the liquid resistance value in the starting process always meet the mechanical property requirements on the on resistance value, thereby causing the motor to obtain the maximum starting torque and the minimum starting current and starting a smooth. Specific work process is: to start the main motor active polar plate in a small power gear system driven by slowly moving, change the distance between the two plates, the string into the rotor circuit of liquid resistance value change meet the above conditions, the motor speed increased. When the distance between the two plates is the minimum, the motor speed of the motor reaches the rated speed, the liquid resistance is short, the starting process is completed, the operation state is transferred.

GV2ME series motor protective circuit breaker

Motor protector is to protect the motor, the motor is overload, lack of phase, short circuit, short circuit, over voltage, under voltage, leakage, three phase unbalance, overheating, bearing wear, stator rotor eccentricity, to alarm or protect the device.

Common types of motor protectors

1, thermal relay: Ordinary small capacity AC motor, working condition is good, there is no frequent starting and other bad conditions of the situation; because of poor accuracy, reliability can not be guaranteed, not recommended.

2, electronic type: detection of three-phase current value, the whole set current value of potentiometer or pull off code switch, circuit is generally used in analog mode, the use of anti time limit or time limit for work. Protection functions including overload, lack of phase, blocking, etc., the type of failure to use the indicator light shows that the operation of the use of digital tube display.

3, intelligent: detection of three-phase current value, the use of single-chip microcomputer, to achieve the motor intelligent integrated protection, set protection, measurement, communication, display as one. The setting current adopts digital setting, operation panel button to operate, the user can according to the specific circumstances of the motor in the field of various parameters correction setting; the use of digital tube as display window, or the use of large screen LCD display, can support a variety of communication protocols, such as ProfiBUS, ModBUS, etc., the price is relatively high, for more important occasions; high voltage motor protection are the use of intelligent protection device.

4, thermal protection: in the motor of the buried thermal element, according to the motor winding temperature of the motor, the protection effect is good, but the motor capacity is large, need to use the current monitoring type, to avoid the temperature of the motor when the temperature rises sharply, due to the delay of the temperature measurement element, resulting in motor winding damage.

5, magnetic field temperature detection: in the motor of the magnetic field detection coil and temperature measurement element, according to the motor internal rotating magnetic field changes and temperature changes in the protection, the main functions include overload, plugging, lack of phase, over heat protection and wear monitoring, protection function is perfect, the need to install magnetic field detection coil and temperature sensor.

schneider ac contactor LC1D series

LC1-D09M7C Schneider AC contactor is widely used in the power of the open circuit and control circuit. It uses the main contact to open and close circuit, with auxiliary contacts to execute control instructions. The main contact is normally open contact, and the auxiliary contact is often two pairs of normally open and normally closed function of the contact, small contactor is also often used as the intermediate relay with the main circuit. The contact of AC contactor, made of silver tungsten alloy, has good electrical conductivity and high temperature resistance.

– the contactor can be composed of a mechanical reversible interlocking magnetic starter, a star delta starter

– contactor is a protective type, and the action structure is a direct acting type, and the contact is a double breakpoint.

– has the characteristics of small size, light weight, low power consumption, long life, safe and reliable, etc.

– according to the user to choose to increase the auxiliary contact group, the air delay is a combination of a variety of first class products

– when installing, should be in accordance with the provisions of the installation, the terminal A1 of the contactor coil in line with the top of the head, consistent with human visual habits

– the contact of the metal mounting base plate shall be properly grounded

– terminal screws should be tightened, check the wiring is correct, should be in the main contact is charged and the attracting coil power several times, action test is reliable, can be put into use

If there is abnormal noise, when in use, may be a core pole on dirt wipe face, please

– use, should be regularly check the product components, the movable part is not stuck, fastening parts without loose, spare parts if there is damage, should be replaced in time

DC Contactors used in electric vehicle

- At Monday October 26th, 2015

- By Jacky Zheng

- In Technology

0

0

Electric vehicle DC contactor is mainly used to control the motor switch;

The contactor adopts modular design, can with minimal parts assembly customer required number of contacts and clients need contact form (normally open, normally closed and conversion). The series products contact breaking high voltage, and the transverse blowing magnetic field quenching, the maximum open circuit voltage can be reached 220VDC. products applicable to the programmable power supply or uninterrupted power supply system, forklifts, electric vehicles, engineering machinery system.

中文

中文