交流接触器国内外主要公司产品概况

- At 2015年10月19日 星期一

- By Jacky Zheng

- In Basic knowledge

0

0

1.ABB公司的B系列、A系列20世纪80年代初,曾由上海人民电器厂、北京低压电器厂作为生产许可形式,技术引进的ABB公司的B系列具有初步模块化结构;之后,又推出了EB、EH系列;90年代推出了A系列。A系列接触器有9~1050A22个电流等级,8种机型,适用的环境温度为:-40℃~70℃,是该接触器的特点。

2.富士公司的SC-E系列SC-E系列是常熟开关制造厂有限公司与富士公司合资的产品,有9~800A18个电流等级,10种机型。除了模块化等特点外,体积小是其亮点。例如,额定电流50A的SC-E25外形尺寸为54mm×90mm×96mm,仅为同电流等级ABB公司产品A50D的50.6%,是施耐德公司产品LC1-D50的38.5%,具有高可靠的接触性能(达DC5V,3mA)。

3施耐德公司的LC1-D系列20世纪80年代前期,天水213机床电器厂引进了施耐德公司的LC1-D系列接触器,是最早进入我国的接触器之一。当时,LC1按电流大小分9~95A的D系列和115~780A的F系列。近年又推出了包含9~620A20个电流等级,8种机型的LC1-D系列。该产品是模块化结构的典型代表,进一步减小了飞弧距离,提高了防护等级,操作频率可高达3600次/h(小电流规格)或2400次/h(大电流规格)。

4西门子公司的3RT系列西门子公司的3RT系列接触器继承了3TB的寿命高、线圈模块化、便于更换的优点,且实现了全塑化及高防护能力(IP2x)。全系列有7~500A19个电流等级,7种机型,机械寿命最高可达3000万次,线圈平均功耗低是其易于同类的特点。

5国内CJ40、CJ45系列等产品该系列产品主要由上海电器科学研究所主导开发的,杭州之江开关厂、上海人民电器厂、天津百利、正泰电器有限公司等生产的CJ40、CJ45系列;天水213厂引进生产的GSC1系列;上海良信电器股份有限公司的NDC1系列等,后两者基本源于LC1的形式。CJ45从6.3~800A19个电流规格,10种机型,机电寿命分别达到1000万次和100万次,具有模块化和全塑化结构,有延时辅触、线圈浪涌抑制、机械连锁等齐全的附件模块,特别是触头采用Ag-Ni(16A及以下)或AgSnO2(16A以上),具有环保意义。

交流接触器辅助触点识别方法

- At 2015年10月10日 星期六

- By Jacky Zheng

- In 技术

0

0

1. 标有NO和NC

NO是英文normal open(常开)的缩写,NC是normal close(常闭)的缩写。

2. 标有数字序号11或12等

后面一位数(1、2)代表常闭触头,(3、4)则代表常开触头,类似的。还有(5、6)、(7、8)代表时间继电器的延时常闭、常开触头组。

3. 交流接触器辅助触点两端是否可以直接接220V交流电?

可以,事实上许多电路的指示灯就是接的220v。

4.辅助触点的作用

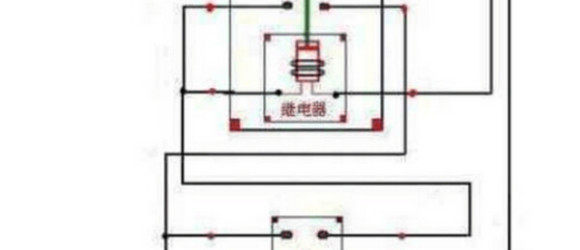

交流接触器有3对主触点,上面的3个接线端子是接电源的,下边的3个接线端子是接用电设备的,吸合线圈接控制回路,当吸合线圈得电铁芯产生磁性,吸合衔铁,主触点接合,用电设备通电工作。另外还有辅助的常开及常闭触电,可用作自锁和互锁控制用。用下面这张图说明常开触点在控制回路中的作用

5.常开常闭的识别方法

用万用表的电阻档测量(不带电的情况下测量)一般情况上下为一组,顾名思义通路(阻值为0或接近0)的为常闭,开路(阻值无穷大)的为常开。

交流接触器的维护和检查

- At 2015年10月03日 星期六

- By Jacky Zheng

- In 常见问题

0

0

交流接触器的运行检查项目

1.检查最大负荷电流是否超过接触器规定的负荷值。

2.检查接触器线圈温升是否低于65度。

3.监听接触器内有无放电声以及电磁系统有无过大的噪声和过热现象。

4.检查触头系统和连接点有无过热烧损现象。

5. 检查灭弧罩是否完整,如有损坏应更换后再运行。

6.检修触头系统,用细挫或细砂纸打光接触面,保持触头原有状态,调整接触面及接触压力,以保持三相同时接触,触头烧损严重的应更换。

7.检查灭弧罩内部附件的完好性,并清擦烟痕等杂质。

8. 检查联动机构的绝缘状况,并检查是否有变形、移位及松脱现象。

9.检查吸合铁芯的接触表面是否光洁,是否有凹凸不平或油污情况,短路环是否断裂或过度氧化及脱出情况,吸合是否良好,断开后,是否返回到正常位置。

10.交流接触器的清洁及周围环境的检查。

11交流接触器的分、合信号指示是否与电路状态相符。

12.电磁线圈有无过热现象,电磁铁上的短路环有无脱出和损伤现象。

13.辅助触点有无烧蚀现象。

14.铁芯吸合是否良好,有无较大的噪声,断开后是否能返回到正常位置。

15.周围的环境有无变化,有无不利于接触器正常运行的因素,如振动过大、通风不良、导电尘埃等。

交流接触器安装及使用注意那些问题

- At 2015年09月21日 星期一

- By Jacky Zheng

- In Basic knowledge

0

0

1 交流接触器运行中的问题

交流接触器是一种应用广泛的控制电器,主要用于控制电动机等用电设备的运行和停止,普通的交流接触器在吸合后,交流接触器的线圈里仍然通着交流电,功耗比较大,所以线圈发热,噪声大比较普遍,不仅浪费电能而且线圈的绝缘容易老化使交流接触器的寿命缩短。

2 交流接触器节能模块的功能与使用效果

在普通交流接触器上使用节能此模块后,交流接触器吸合状态下功耗大幅度降低,线圈温度也会大大降低,可以使接触器线圈的绝缘层不因为高温而老化,从而延长接触器的使用寿命。交流接触器吸合状态下噪音大幅度降低,改善接触器使用场所的环境条件。普通交流接触器一般只能在线圈额定电压85%~110%的范围内工作,当线圈两端电压高于额定电压的110%时,交流接触器线圈有可能会因为发热而烧毁,在接触器上加装此模块后,交流接触器承受电压波动的能力增强,在操作电源电压过高的情况下,交流接触器线圈也不会因为发热而烧毁。

加入该模块后接触器吸合的声音清脆有力,吸合状态下的电流仅为不加装模块时的10%~40%,节电率为90%~60%。而且接触器吸合后的噪音降低,长时间使接触器保持吸合,接触器线圈表面无明显的温升,甚至还有凉的感觉,对CJ20-400A接触器试验,未加节能模块(线圈电压220V)接触器在吸合后达到稳定状态时的电压为220V、电流为0.615A、噪音为52.5dB、温度为105.2℃,安装模块后,达到稳定状态时的电压为220V、电流为0.184A、噪音为36.6dB、温度为26.8℃,视在功率的节电率为70%。由以上试验可以看出:在接触器线圈回路里加装QCJ交流接触器节能模块后,接触器的电流、噪音、温升均大幅下降,证明模块对交流接触器具有减小线圈回路电流、降低噪音、降低温升的作用。

现在康保县所有路灯已经安装了该模块,彻底解决了接触器晚上工作时噪声对居民的干扰,节省了大量电费。

3 交流接触器节能模块的安装应用

在模块的顶部有两个输入接线端子,下部两侧各有两个输出导线,将模块下部的两根输出导线接交流接触器线圈的接线端(A1、A2),将模块顶端的输入接线端接交流接触器的控制电路。

节能模块的工作电压为AC220V,输入端只能接入220V的操作电源,严禁接入380V电源,但本模块的输出却可以驱动线圈额定电压为380V的交流接触器,此点请特别注意!

具体操作方法如果接触器线圈电压为220V,则只需将原接交流接触器线圈的导线从接线端子上拆下,接到本模块的输入端子上,再把本模块的输出导线接交流接触器的线圈即可(即把本模块串接到接触器的线圈回路里)。如果原接触器线圈电压为380V,则要把本模块串到交流接触器的线圈回路里,同时还要把原控制线路两根电源线中的一根改接到工作N线上(原来的控制电源线接两根相线,电压为380V,现把其中的一根线改接到工作N线上,使控制电压改变为220V),如果原控制线路里还有额定电压为380V的指示灯、中间继电器、时间继电器等元件,还要把这些元件更换为额定电压为220V的元件。

电机起动器接触器

- At 2015年09月16日 星期三

- By Jacky Zheng

- In Basic knowledge

0

0

起动器

控制电动机起动和停止用的电器。电动机起动时,起动电流要超过电动机额定电流很多倍,起动电流大时线路的电压暂时要有所降低。线路容量较大的情况下电压降低不多,对线路上的其他电器设备的工作影响不大,因此,中小容量的交流电动机可采用直接起动方式。如果线路电压降低较多,一方面会影响线路上其他设备的运行,另一方面电动机的起动转矩将减小,起动发生困难,甚至起动失败,因此,需要采用起动器。

起动器按操作方式分为手动和自动两类。交流电动机的手动起动器中比较常用的有星-三角起动器,它属于降压起动方式。在起动时,先将交流三相电动机的绕组接成星形,使每相绕组的外加电压降低为相电压,以减小起动电流的冲击。起动过程中手动操作将三相绕组转换成三角形接法,将每相电压升高到线电压后完成起动。直流电动机的手动起动器是在电机的绕组电路中串入限流电阻,以限制起动电流,用手动操作逐段地切除串联电阻,直流电动机的转速逐步上升,直至全部串联电阻切除后起动完成。自动操作起动器又分为直接起动和减压起动两种。常用的直接起动器是电磁起动器,具有失压和过载保护功能。直接起动器又分不可逆和可逆两种。不可逆起动器只能完成电动机的起动和停止功能;可逆起动器可完成正向旋转起动、反向旋转起动及停止功能。自动减压起动器有自耦减压起动器、频敏起动器和综合起动器等。

English

English